The Technology

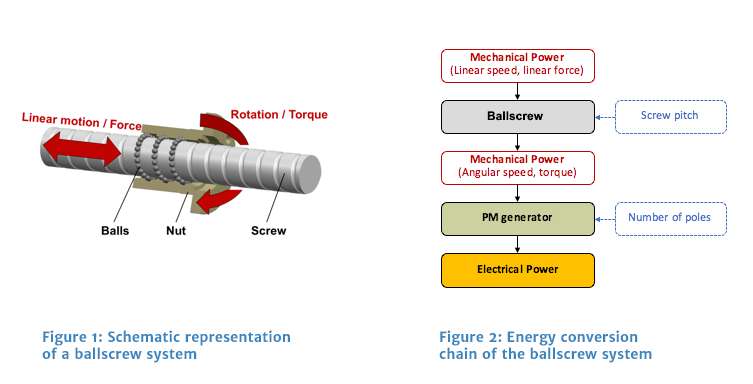

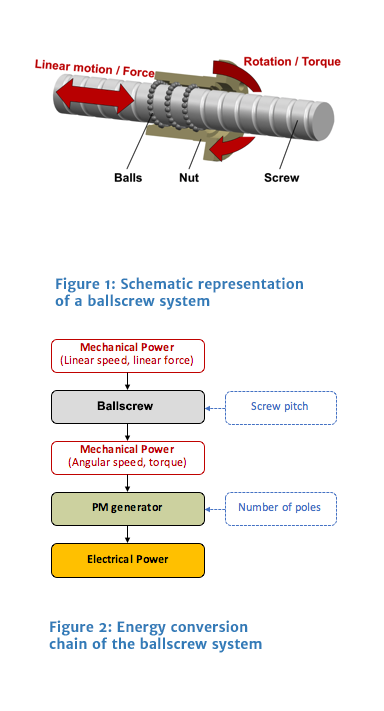

The Electro-Mechanical Generator (EMG) is an innovative type of Power-Take-Off (PTO) that can be applied to most of the Wave Energy Convertors (WECs) currently available in the market. The core element of the EMG is a ballscrew. This is based around a screw, which is a mechanical component that can convert linear motion into rotary motion and vice-versa. This concept is easy to understand if we think of the screws we use, e.g. to mount a shelf on the wall at home. A cutaway schematic of the ballscrew system is shown in Figure 1 with the energy conversion chain in Figure 2.

The ballscrew is a mechanical device in which the balls, acting as low friction load-carriers, efficiently convert the low-speed linear motion of the screw into a high-speed rotary motion of the nut. The rotational speed of the nut is a function of the screw linear speed and the screw pitch (i.e. the axial distance between adjacent threads on the screw).

Permanent magnets are integrated in the nut, which acts thus as rotor of the electrical generator. The rotor, spinning inside a bespoke-designed stator, induces a voltage on the stator windings thanks to the principle of electromagnetic induction. The frequency of the induced voltage is proportional to the number of poles of the generator. The high rotational speed of the nut and generator rotor increases the induction rate and thus the overall system compactness.